There are many different specialized processes to consider when choosing which grinding methods and machines are right for a particular job or project requirement. When there are large components that need to have stock removed from one side, Blanchard grinding is the process most often selected.

Typically and historically Blanchard grinding has been used exclusively with ferrous metals. However, today with more components now made of plastics and high strength polymers, the process can be modified to be highly effective for those parts as well. It is also used for non-ferrous types of metals with slight adjustments to the actual technique and equipment in use.

The Technique and Process

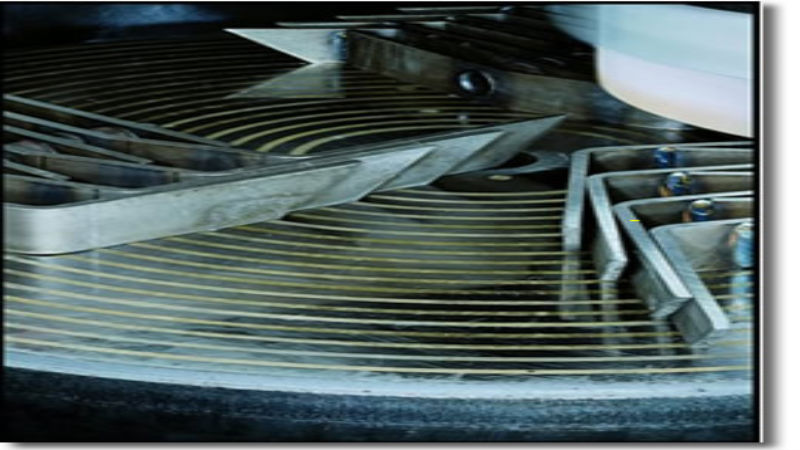

All Blanchard grinding techniques and processes provide rotary surface grinding, and there is a typical rotary grinding surfacing left on the metal or non-metal component after the grinding is complete.

With ferrous materials, the component is held in place on the grinding machine with a magnetic check. The grinding wheel itself is attached to a vertical spindle. The rotation of the magnetic chuck holding the component and the grinding wheel on the spindle are opposite to each other.

This process quickly removes stock from large components including plate stock and even for large die blocks. As the movement of the vertical spindle and the magnetic chuck, or modified chuck with non-ferrous alloys or plastics, can be carefully controlled, it is possible to produce very high tolerances even across large surface areas.

The Benefits

The most obvious benefit to Blanchard grinding is that the complete surface area can be easily ground using a single pass or multiple passes with the equipment. This allows for uniform tolerances across even a large surface area that would not be possible with other rotary grinding techniques and equipment.

Additionally, the process can be repeated time and time again to extremely tight tolerances. This is essential in the production of large orders of parts and components or even for single unit prototype runs.

The key to setting up and managing the Blanchard grinding process is to have the experience in working with the different metal alloys as well as the different options in grinding wheels. With different materials, there may be some differences in the tolerances that can be achieved, but it is not uncommon for ferrous metals to go through the Blanchard grinding process and result in surface flatness and tolerances of 0.001 inch, all featuring the traditional cross-hatched finish, a true sign of quality grinding.