Blanchard Grinding, also known as rotary surface grinding, is the process of quickly removing stock from a side of a part that is normally too large to be doubled disc ground. Large parts can be Blanchard ground on a large machine. The process removes a significant amount of stock quickly and efficiently. The name comes from the Blanchard Machine Company – a firm that specializes in rotary grinding machines.

For Large Parts

Large parts like vacuum chambers, mold plates and rotary tables can be Blanchard ground. The process also helps in adding size versatility, eliminating mismatching and speeds the overall turnaround time on the production of larger parts compared to fly cutting. It also helps provide your company with considerable time savings when compared to other processes like surface grinding. It is used in the process of grinding various stock pieces including;

Rotary tables

Plate stock

Die blocks

The Machine

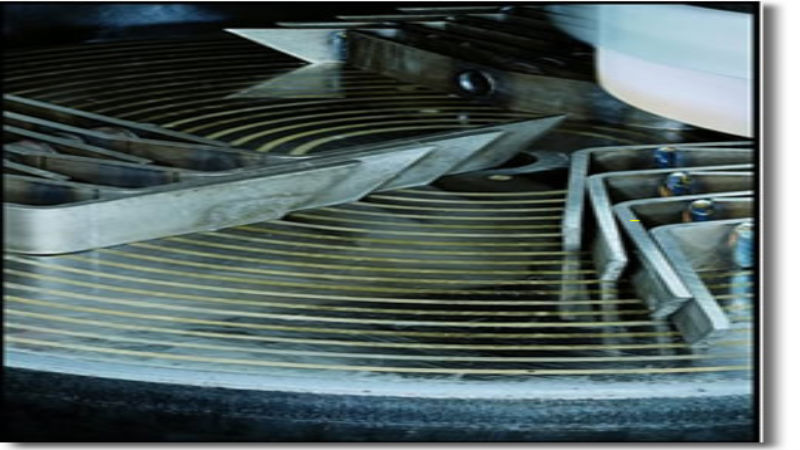

The machine used for Blanchard grinding is distinguishable by the position of the grinding wheel. It is mounted on a vertical spindle. As the when turns counter to the rotation of a magnetic chuck, the chuck holds the ferrous metal in place. However, this does not mean that the machine will not work on plastics or non-ferrous metals. For such materials, a clamp is added to hold them. This means an increase in production time and overall costs associated with grinding.

The machine also requires significant amounts of power to operate effectively and efficiently, making the operation of the grinding machine more expensive. However, the greater horsepower requirements are quickly offset by the increased capability and speed of the machine to handle tasks with efficiency and speed – reducing production time.

During grinding, a particular finish pattern appears that is unique to the machine. This is as a result of the movement of the machine is it works its way across the surface. It is also a unique feature to the entire grinding process.

Advantages of Precision Machining

Precision machining using the Blanchard machine offers a wide variety of components used on a daily basis. Precision machining is actually one of the most important techniques in the machining industry that offers;

Increased production efficiency that surpasses human abilities

The eradication of the human error factor using CNC (Computer Numerically Controlled) machines for precise components

Quicker assembly features that eliminate the need for manual assembly, allowing human hands to work on larger projects since production time is greatly reduced

Significant material waste reduction during the production of high-quality components and parts

This type of rotary surface grinding offers you assured dependability, quality and uniformity.